|

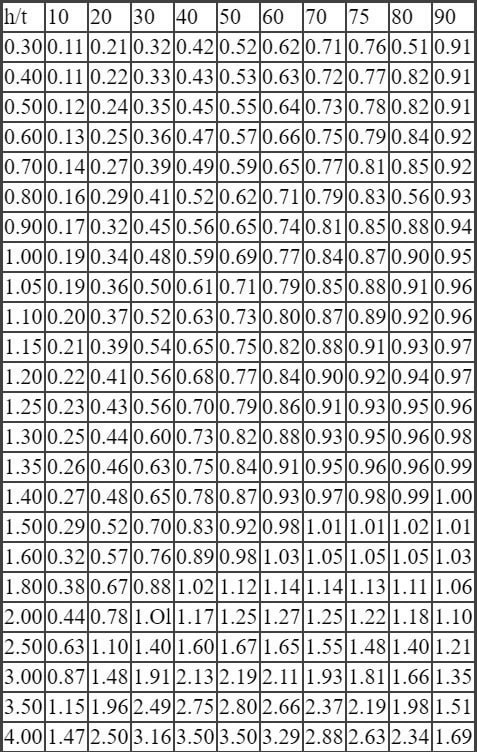

Simplified Procedure for Approximate Load Calculations

Dynamic loading of disc springs occurs when the load continuously changes from preload to final load.

|

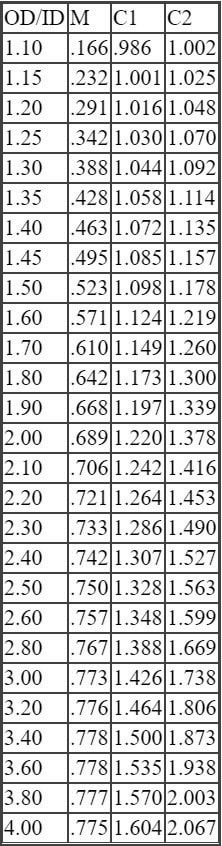

Disc Spring Stress Calculations

For evaluation of compressive stress, use formula S1. It compute the compressive stress at the upper inner diameter. This compressive stress may be as high as 400,000 psi for certain bolted applications.

For dynamic applications, it is necessary to consider the tensile stresses at the points marked S2 and S3. The stresses at these points depend on the ratio of diameters () and the spring characteristic (C) as well as the deflection (f). This stress should not exceed 200,000 psi at .75h deflection. |