Metric Disc Springs for Flange Applications

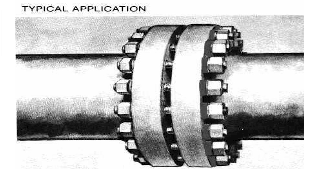

Spring Discs are an elastic mechanical element. When used in bolt joints that are subject to thermal or mechanical shock, they deflect and move with the bolted joint. Hence, they compensate for developed looseness. The reactive power of the spring disc serves to keep the bolt joint tight under all conditions. Principal applications include piping construction, compression joints, steam piping joints, valve and pump connections, and others in the petrochemical field.

A principal cause of flange leakage is abnormally high loads produced by thermal expansion and contraction of a bolted joint. Generally, flanges are under static load conditions. However, in large piping systems, there may also be mechanical shock from compressor related piping. Thermal and mechanical shock differential can cause variation and yielding in bolt loads. To protect against these conditions, always use spring discs under the nut or bolthead. Pre-stressing or torquing the bolt at factory installation is not sufficient to protect the flange joint under unexpected temperature variations and mechanical shock loads in the field. By absorbing peak stresses, spring discs prevent damage to the bolt, gasket and joint. Part Numbers include MFL8050, MFL8078, MFL10078, MFL12090, MFL20160, MFL24160, MFL27168, MFL30190, MFL36250, MFL39250

|

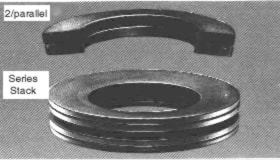

*For single spring disc; for higher loads, use parallel stacks. Note: Load calculated for 17/7 PH stainless steel with large radii, R = t/4

Material: STAINLESS: 17/7 PH (Armco) precipitation hardened Hardness: Rc-38-43 TEMPERATURE RANGE: -220 C to +300 C For higher temperatures, to +600 C we can supply Inconel X-750 (non standard) Note: For normal operating temperatures, we can supply Chrome Vanadium SAI 6150.

Tolerance: OD - Plus .000/Minus 1.5% x OD (designed for standard Flange spot face diameter) (D-Minus .000/Plus/Minus 1.5% ID THICKNESS - Plus/Minus 5% x normal thickness shown LOAD - Plus/Minus 20% of nominal shown (when ordering, ALWAYS specify materials after part number) |